Exposing congestion patterns and idle time across inbound–picking–dispatch flows using process intelligence

Case Study Snapshot

Industry: Warehousing & Distribution

Region: United Kingdom

Facility Type: High-volume distribution centre

Core Challenge: Warehouse congestion limiting throughput

Zenotris Capability: Process intelligence for warehouse flow optimisation

Measured Outcome: 14% throughput increase

Labour Impact: No additional headcount

Today’s logistics economy rewards innovators. Technology is no longer considered a luxury; it is the foundation of competitiveness. Those who use tools like process intelligence increase their resilience, visibility, and agility. These characteristics are crucial in marketplaces experiencing change, uncertainty, and increased customer demands.

Firms that fail to innovate risk falling behind. Manual oversight cannot keep up with the complexities of global logistics. While competitors streamline and optimize, laggards lose money, customers, and reputation. In a business where every second counts, inefficiency may soon become the costliest liability.

Technology enables logistics organizations to not only survive, but grow. Businesses achieve long-term growth by combining data and action. others that act early have a competitive advantage over others who wait until inefficiencies destroy value.

The Operational Challenge: When Busy Warehouses Underperform

The client operated a high-throughput distribution centre serving retail and wholesale customers across the UK.

Despite full staffing levels and extended shifts during peak periods, the warehouse consistently faced:

- Congested inbound and outbound zones

- Delays between picking, staging, and dispatch

- Idle time for pickers and equipment

- Missed daily throughput targets

Leadership suspected capacity constraints — but adding labour or expanding floor space was not commercially viable.

The question was simple:

Why was a fully staffed warehouse still underperforming?

Why Traditional Warehouse KPIs Gave the Wrong Answer

Warehouse performance was tracked using familiar metrics:

- Pick rates per hour

- Dock utilisation

- Shift productivity reports

While these metrics showed activity, they failed to explain flow disruption.

Teams were working hard — but work was not flowing smoothly across inbound, picking, and dispatch.

Zenotris Approach: Warehouse Flow as a Process, Not a Department

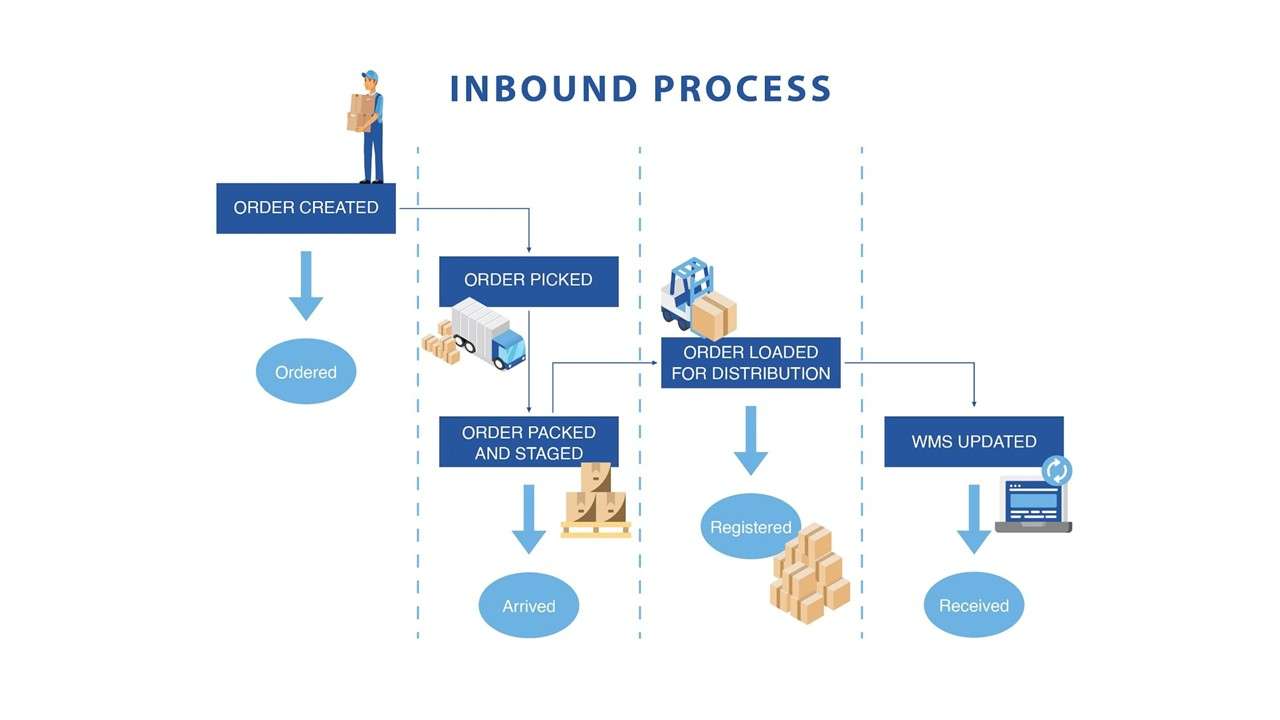

Zenotris applied process intelligence for warehouse operations, analysing the end-to-end execution flow across:

⚪ Inbound receipt and putaway

⚪ Picking and internal movement

⚪ Staging, loading, and dispatch

Using event-level data from WMS and equipment logs, Zenotris reconstructed how inventory and tasks actually moved through the facility — minute by minute.

This revealed congestion patterns, idle gaps, and hidden queues that traditional reporting could not capture.

What We Discovered

Process intelligence uncovered several systemic issues:

⚪ Inbound surges were overwhelming picking zones at specific times

⚪ Pickers frequently waited for staging space to clear

⚪ Dispatch docks experienced uneven utilisation

⚪ Equipment and labour idle time spiked during handoffs

Critical Insight

Congestion was created internally by process timing — not by volume or labour shortages.

A small number of poorly sequenced flows were slowing the entire warehouse.

Zenotris worked with site operations to implement flow-based adjustments, including:

- Rebalancing inbound release timing

- Sequencing pick waves to reduce downstream congestion

- Adjusting staging and dispatch prioritisation

- Aligning labour deployment with real-time flow demand

No new systems.

No layout changes.

No additional staff.

Measured Results

Within weeks, the warehouse achieved:

- 14% increase in daily throughput

- Reduced congestion in staging and dispatch zones

- Lower idle time for pickers and handling equipment

- Improved on-time dispatch performance

The facility delivered more output using the same resources.

Operational Improvements Implemented

Why This Worked

⚪ Warehouse event data already existed — it just wasn’t connected

⚪ Congestion was process-driven, not people-driven

⚪ Small sequencing changes created disproportionate gains

⚪Improvements were practical and immediately executable

This was not a warehouse redesign project.

It was flow optimisation based on operational truth.

What This Means for UK Warehouse & Operations Leaders

If your warehouse shows signs of:

⚪ Congestion despite full staffing

⚪ Missed throughput targets

⚪ Idle time alongside bottlenecks

⚪Pressure to add headcount or space

The issue is likely how work moves, not how hard people work.

Zenotris helps warehousing operations unlock hidden capacity using process intelligence — fast, measurable, and without disruption.