Turning WMS event logs into practical warehouse design improvements

Case Context

This case involves a UK-based distribution centre handling a large number of SKUs for retail and e-commerce fulfilment. The operation relied heavily on manual picking and was under constant pressure to increase output during peak demand.

Pick rates looked acceptable at a high level, yet supervisors consistently reported fatigue, uneven performance between shifts, and longer pick cycles than expected. Adding labour was an option — but not a sustainable one.

The real question was whether the warehouse layout and slotting logic still reflected how orders were actually being picked.

Today’s logistics economy rewards innovators. Technology is no longer considered a luxury; it is the foundation of competitiveness. Those who use tools like process intelligence increase their resilience, visibility, and agility. These characteristics are crucial in marketplaces experiencing change, uncertainty, and increased customer demands.

Firms that fail to innovate risk falling behind. Manual oversight cannot keep up with the complexities of global logistics. While competitors streamline and optimize, laggards lose money, customers, and reputation. In a business where every second counts, inefficiency may soon become the costliest liability.

Technology enables logistics organizations to not only survive, but grow. Businesses achieve long-term growth by combining data and action. others that act early have a competitive advantage over others who wait until inefficiencies destroy value.

The Problem on the Floor

Over time, the warehouse layout had evolved organically. Products were moved as space became available, seasonal demand changed, or new lines were introduced. Slotting rules existed, but they were largely static.

This led to several day-to-day issues:

- Pickers covering excessive walking distances per order

- Frequent backtracking within aisles

- High-frequency items stored far from natural pick paths

- Replenishment activity interfering with picking flow

None of these issues appeared clearly in standard WMS reports. Productivity was measured — movement was not.

Why Traditional Slotting Analysis Didn’t Help

Previous slotting exercises were based on:

- ABC velocity classifications

- Periodic demand snapshots

- Spreadsheet-based assumptions

What they missed was how SKUs were picked together, and how pickers actually moved through the warehouse when fulfilling real orders.

The result was a layout that made sense in theory, but not in daily execution.

How Zenotris Approached the Problem

Zenotris analysed raw WMS event logs rather than summary reports. This included:

⚪ Pick start and completion timestamps

⚪ SKU visit sequences within orders

⚪ Zone transitions during picking

⚪ Order batching behaviour

Instead of asking how picking should happen, the analysis focused on how it actually happened, across thousands of completed orders.

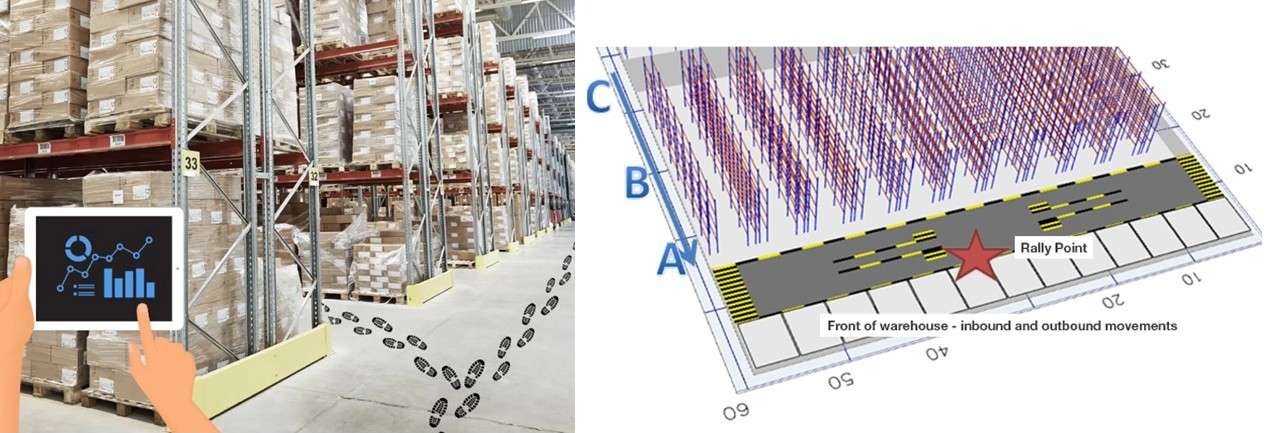

This made it possible to reconstruct real pick paths and identify where unnecessary travel was being introduced.

What the Data Showed

The analysis revealed clear, repeatable patterns:

⚪ Certain SKUs appeared in a high percentage of orders but were located on the periphery

⚪ Some low-volume items were forcing long detours during otherwise efficient pick routes

⚪ Pickers were frequently crossing the same zones multiple times within a single order

⚪Replenishment locations conflicted with peak picking paths

A relatively small number of slotting decisions were responsible for a large share of wasted movement.

Based on these findings, the warehouse team implemented targeted slotting changes:

- High-frequency SKUs were relocated closer to natural pick paths

- Products commonly picked together were placed in proximity

- Slow movers were moved out of primary pick zones

- Replenishment locations were adjusted to reduce path interference

No automation was added.

No physical expansion was required.

All changes were made within the existing layout.

Measured Results

After implementation, the operation recorded:

- 19% reduction in average pick path distance

- Shorter pick cycles per order

- Less physical strain on pickers

- More consistent performance across shifts

The reduction in travel translated directly into labour efficiency and higher effective capacity, especially during peak periods.

Changes Implemented

Why This Case Matters

This was not a performance management issue.

It was not a labour issue.

And it was not a technology issue.

It was a design issue hidden inside operational data.

By using real execution data instead of assumptions, the warehouse was redesigned around how work truly flowed — not how it was documented.

What This Means for Warehouse Operations

If your warehouse shows signs of:

⚪ Excessive walking despite stable volumes

⚪ Picker fatigue without clear productivity gaps

⚪ Pressure to add headcount during peaks

⚪ Layout decisions based on outdated demand logic

Then the opportunity may lie in slotting and pick path design, not effort or staffing.

Zenotris helps warehouses turn existing WMS data into practical, measurable layout improvements — without disruption.