Executive Summary

A global manufacturing company in India, partnered with Zenotris to overhaul its production planning and operations amid recurring inefficiency, inventory disruptions, and slow decision cycles. By deploying advanced process intelligence solutions, Zenotris enabled the client to achieve significant improvements in delivery performance, productivity, and cost control—all supported by real-time analytics and actionable process insights.

Background

Pre-Transformation Situation

Prior to engagement, the manufacturing operation struggled with:

- An average 2–4 hour delay per production order release.

- 18% of monthly runs are delayed by unplanned component shortages, leading to a 12% loss in output.

- Data refresh lag of 6 hours, hampering responsiveness during production shifts.

- Manual exception handling in 30% of workflows, introducing variability and error risk.

- Disparate KPI sources and a 48-hour reporting delay, stalling swift management action.

- On-Time Delivery (OTD) rates at 64%, below a competitive industry benchmark of 80%.

Engagement Objectives

The specific business goals were:

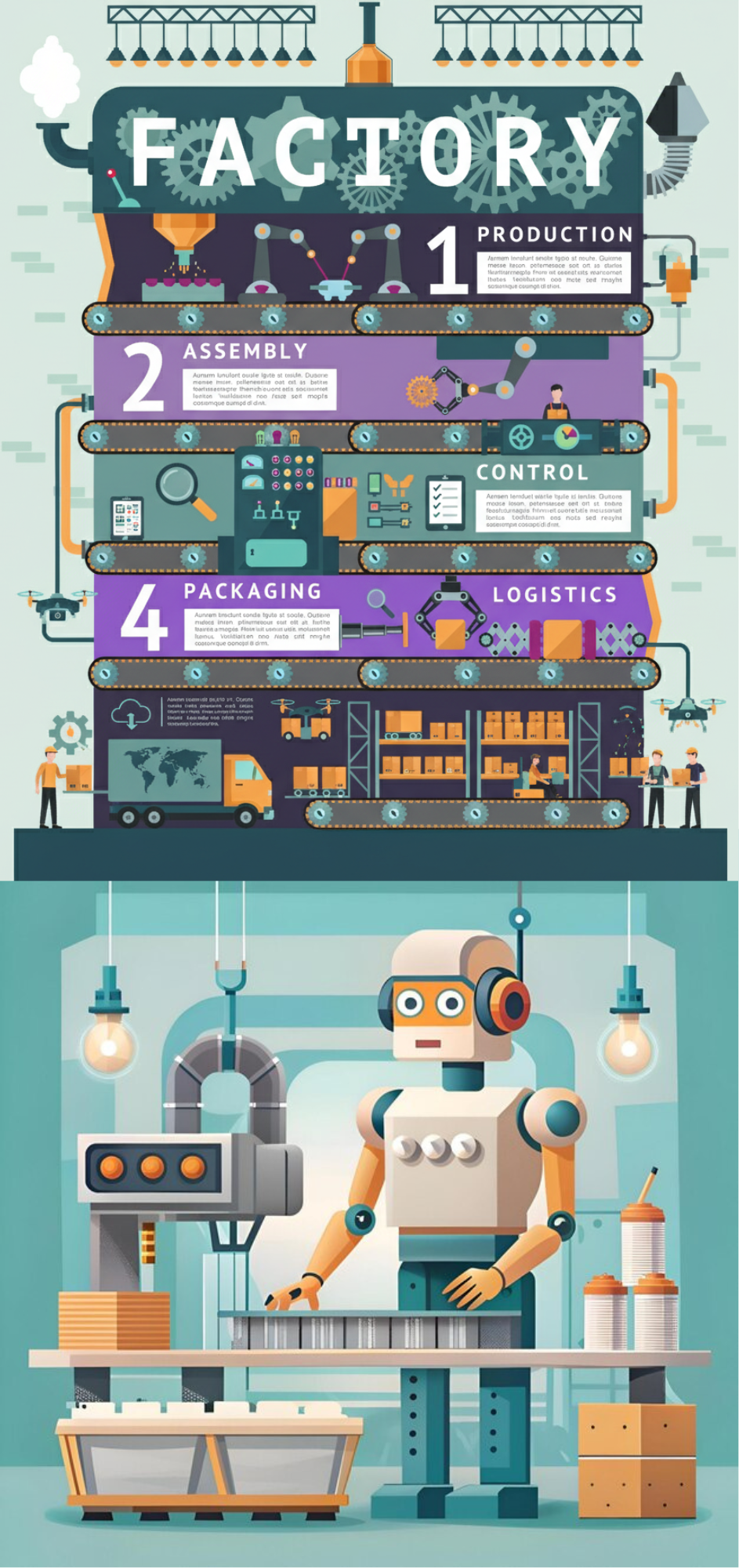

- Achieve real-time end-to-end process visibility from order release through finished goods.

- Quantify and drastically reduce bottlenecks in planning, inventory allocation, and production.

- Deliver unified KPI dashboards for leadership, enabling rapid, data-driven action.

- Stabilize and increase On-Time Delivery performance to match leading benchmarks.

Solution Approach

Process Mapping & Root Cause Analysis

Zenotris integrated process event logs across ERP and MES platforms, combining machine data with order, material, and labor records. This created:

- A live digital twin of the factory floor.

- Transparent visibility into bottlenecks from planning to dispatch.

- Automated anomaly detection to alert on exceptions and deviation from standard flows.

Predictive Analytics

Leveraging historical and in-process data, Zenotris’ solution:

- Forecasted inventory depletion and flagged at-risk lines before stoppage occurred.

- Predicted OTD risks by correlating planning, supply chain, and execution lag data.

- Enabled proactive scheduling—adjusting labor, routing, or material supply dynamically.

Executive Dashboards & KPI Framework

Implemented best-practice KPI dashboards including:

- Real-time OTD rates, top bottleneck causes, and deviation frequencies.

- Root cause drill-down (e.g., line-level downtime, shortfall incidents, manual overrides).

- Historical performance trending and benchmarking against industry standards.

Automated Data Integration

Refactored legacy ETL processes reduced system refresh latency from 6 hours to just 2, ensuring up-to-date metrics for every production shift and continuous improvement cycle.

Change Management & Adoption

A comprehensive training and governance program ensured buy-in, drove user adoption, and embedded continuous improvement practices throughout teams and leadership.

Quantitative Results ( 9-Month snapshot)

During the course of the process intelligence transformation, Zenotris delivered dramatic improvements in the client’s operational metrics.

| Metric | Before | After | Improvement |

|---|---|---|---|

| Order Release Delay | 2–4 hrs/order | ≤30 min/order | >70% reduction |

| Component Shortage Downtime | 18% monthly | 9% monthly | 50% reduction |

| Line Stoppage | 12% lost output | 2% lost output | >80% reduction |

| Data Refresh Interval | 6 hours | 2 hours | 67% faster |

| On-Time Delivery Rate (OTD) | 64% | 79% | +15 pts (nearing 80%) |

| Process Variability (Manual Steps) | 30% | 13% | >55% reduction |

| KPI Reporting Lag | 48 hours | <2 hours | 95% faster |

| Estimated Annual Cost Avoidance | — | — | 8% annual production cost saved |

Value Delivered

Increased Revenue : Higher OTD led to fewer penalties, greater customer trust, and improved potential for capturing new business.

Resource Optimization: Fewer stoppages freed up 240+ hours of productive time per month.

Proactive Operations: Real-time bottleneck alerts and predictive replenishment slashed the impact of unforeseen disruptions.

Leadership Agility: Unified dashboards accelerated response time to issues by over 90%, enabling daily management interventions instead of weekly.

Cultural Shift: Persistent process monitoring and transparent reporting fostered a culture of continuous improvement and accountability.

Lessons learned & next steps

Real-time process intelligence delivers measurable gains in productivity, reliability, and agility when deployed with strong cross-functional adoption.

To sustain gains, ongoing review of process mining insights and periodic recalibration of dashboards are recommended, ensuring alignment as business conditions evolve.

Conclusion

Zenotris’ data-driven approach transformed the client’s production environment—establishing transparent, agile, and resilient operations. The solution empowered both plant and executive teams to act faster, prevent disruption, and pursue operational excellence with confidence.