Optimising picking, packing, and exception handling using process intelligence

Case Context

This case involves a UK fulfilment centre handling a mix of retail replenishment and direct-to-consumer orders. Volumes were growing steadily, but labour costs were rising faster than output.

Overtime had become routine, exception queues were expanding, and supervisors were constantly reallocating staff to keep orders moving. Despite this, headcount reductions were not an option — both for operational and people reasons.

The objective was clear:

It was to recover lost time inside everyday processes.

Today’s logistics economy rewards innovators. Technology is no longer considered a luxury; it is the foundation of competitiveness. Those who use tools like process intelligence increase their resilience, visibility, and agility. These characteristics are crucial in marketplaces experiencing change, uncertainty, and increased customer demands.

Firms that fail to innovate risk falling behind. Manual oversight cannot keep up with the complexities of global logistics. While competitors streamline and optimize, laggards lose money, customers, and reputation. In a business where every second counts, inefficiency may soon become the costliest liability.

Technology enables logistics organizations to not only survive, but grow. Businesses achieve long-term growth by combining data and action. others that act early have a competitive advantage over others who wait until inefficiencies destroy value.

The Problem Beneath the KPIs

From a reporting perspective, the site tracked:

- Orders per labour hour

- Pick and pack rates

- Daily output by shift

At a glance, performance appeared reasonable. On the floor, however, the picture was very different:

- Pickers waiting for packing stations to become available

- Packers stopping work to resolve missing or incorrect items

- Team leads pulled away from planning to handle exceptions

- Frequent mid-shift labour reshuffling

The operation was busy — but time was leaking away in small, repeated disruptions.

Why Traditional Labour Reviews Didn’t Solve It

Previous productivity efforts focused on:

- Individual performance metrics

- Time-and-motion studies

- Shift-level output comparisons

These approaches treated picking, packing, and exception handling as separate activities.

What they missed was how often work paused, restarted, or looped back between teams — consuming labour hours without showing up clearly in reports.

How Zenotris Looked at the Operation

Zenotris analysed event-level data across the full fulfilment flow, including:

⚪ Pick completion and handover timestamps

⚪ Pack start, pause, and completion events

⚪ Exception creation, resolution, and rework cycles

⚪ Order closure and dispatch confirmation

Instead of asking how fast people worked, the analysis focused on where labour time was being absorbed by waiting, rework, and interruptions.

This made it possible to see how labour was actually used across a normal working day.

What the Analysis Revealed

Several consistent patterns emerged:

⚪ Packing regularly stalled due to late or incomplete picks

⚪ A small group of orders generated repeated exceptions

⚪ Experienced staff were repeatedly pulled into firefighting

⚪ Early delays created disproportionate labour losses downstream

Key insight:

A relatively small share of orders was responsible for a large share of lost labour time.

The issue was not effort or skill — it was process friction.

Working closely with site leadership, Zenotris supported a set of practical changes:

- Clearer handoff rules between picking and packing

- Early identification of orders likely to create exceptions

- Simplified exception resolution paths

- Reduction of repeat rework by addressing upstream causes

No contracts were changed.

No roles were removed.

No additional systems were introduced.

The focus stayed firmly on making work easier to complete correctly the first time.

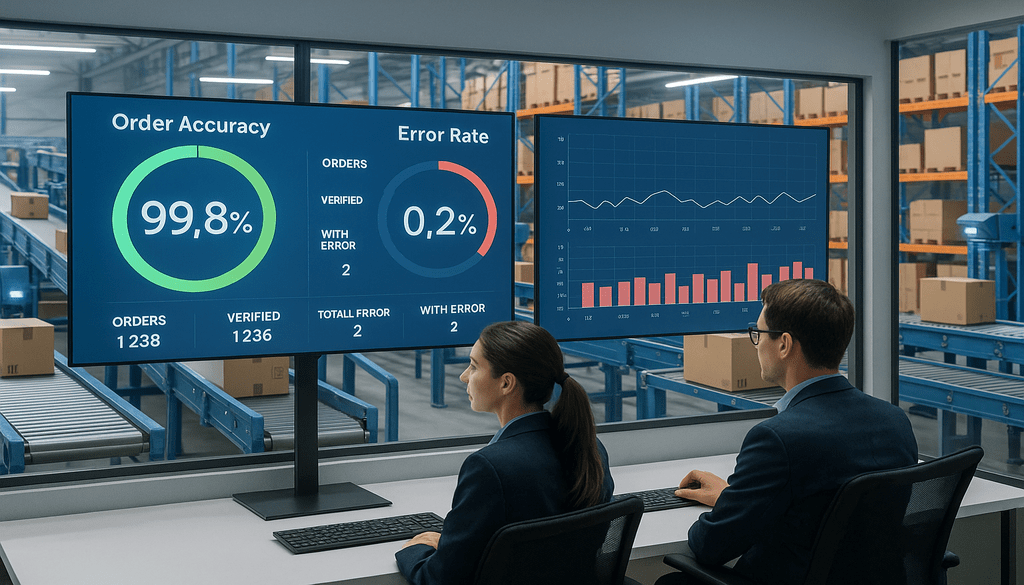

Results Achieved

Within weeks of implementation, the fulfilment centre recorded:

- 11% improvement in labour productivity

- Reduced reliance on overtime during peak periods

- Fewer mid-shift labour reallocations

- Smoother coordination between picking, packing, and dispatch

Crucially, these gains were achieved without layoffs and without increasing workload pressure.

Changes Implemented

Why This Case Stands Apart

This was not a cost-cutting exercise.

It was not automation-led.

And it was not about pushing people harder.

It was about recovering time lost to everyday inefficiencies that had quietly become normal.

Process intelligence made those losses visible — and fixable.

What This Means for UK Fulfilment Operations

If your fulfilment centre struggles with:

⚪ Rising labour costs despite stable volumes

⚪ Overtime driven by exceptions and rework

⚪ Teams constantly stepping in to unblock other teams

⚪ Productivity targets that feel permanently out of reach

The opportunity likely lies in how work flows between people, not in staffing levels.

Zenotris helps fulfilment centres reclaim lost labour capacity by improving processes — not cutting jobs.