Using process intelligence to eliminate hidden WMS–TMS handoff delays in UK logistics operations

Case Study Overview

Industry: Logistics, Warehousing & Supply Chain

Region: United Kingdom

Business Type: Multi-site logistics operator serving retail and e-commerce clients

Core Challenge: Missed delivery windows, penalty costs, and operational firefighting

Solution: Zenotris Process Intelligence for WMS–TMS workflow optimisation

Time to Impact: 90 days

Today’s logistics economy rewards innovators. Technology is no longer considered a luxury; it is the foundation of competitiveness. Those who use tools like process intelligence increase their resilience, visibility, and agility. These characteristics are crucial in marketplaces experiencing change, uncertainty, and increased customer demands.

Firms that fail to innovate risk falling behind. Manual oversight cannot keep up with the complexities of global logistics. While competitors streamline and optimize, laggards lose money, customers, and reputation. In a business where every second counts, inefficiency may soon become the costliest liability.

Technology enables logistics organizations to not only survive, but grow. Businesses achieve long-term growth by combining data and action. others that act early have a competitive advantage over others who wait until inefficiencies destroy value.

The Logistics Challenge: Missed Delivery Windows in the UK

The client was experiencing frequent missed delivery windows, resulting in:

- Financial penalties from retail customers

- Increased fuel and re-delivery costs

- Manual coordination between warehouse and transport teams

- Declining service-level performance despite stable order volumes

Although the organisation had WMS and TMS systems in place, leadership lacked clarity on where delays were actually occurring within the order-to-delivery process.

Traditional logistics dashboards showed late deliveries — but not why they were late.

Why Traditional WMS & TMS Reporting Was Not Enough

- Warehouse Management System (WMS) and Transport Management System (TMS) data were reviewed separately

- Root causes were attributed broadly to “warehouse delays” or “transport constraints”

- Investigations were manual, time-consuming, and incident-based

- Teams focused on reacting to failures instead of preventing them

The real issue was hidden in handoff delays between systems and teams — invisible to standard reporting tools.

The Zenotris Process Intelligence Approach

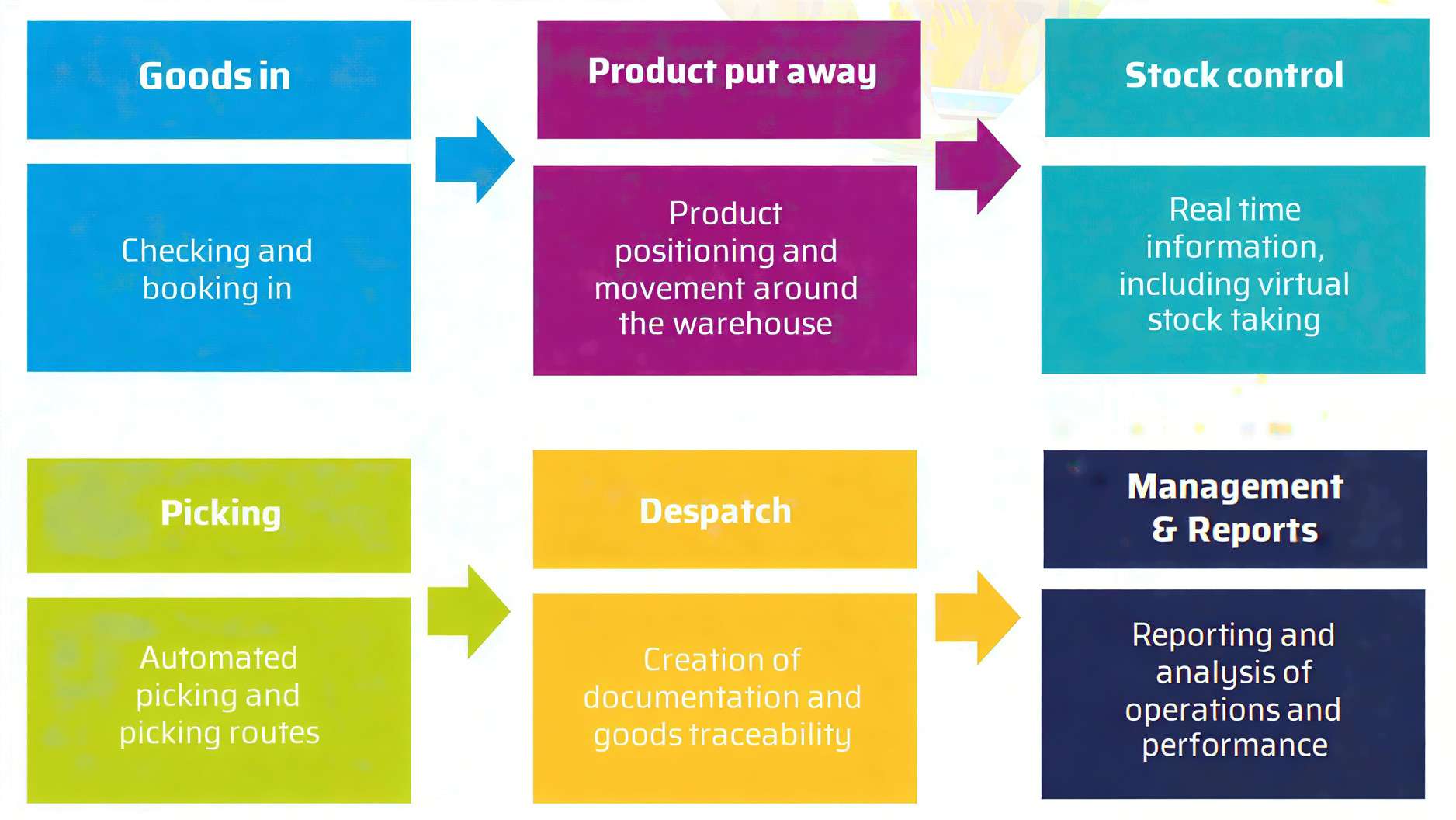

Zenotris applied process intelligence for logistics operations, reconstructing the actual end-to-end execution flow across:

⚪ Order release and pick completion (WMS)

⚪ Load planning and dispatch execution (TMS)

⚪ Delivery confirmation and exception handling

Instead of dashboards, Zenotris created a process flow model based on real event data, revealing:

⚪ How orders truly moved through the system

⚪ Where time was lost between handoffs

⚪ Which exceptions caused repeated delays

⚪ How execution differed from planned workflows

This enabled operations teams to see the reality of their logistics processes, not assumptions.

Key Insights Uncovered

Process intelligence analysis showed that missed delivery windows were not caused by labour shortages or late picking, but by:

⚪ Delays between pick completion and load planning

⚪ Orders waiting in “ready” status without dispatch

⚪ Manual exception handling creating queue congestion

⚪ Inconsistent cut-off adherence between warehouse and transport teams

Critical Finding

⚪ 12% of orders caused more than 40% of missed delivery windows

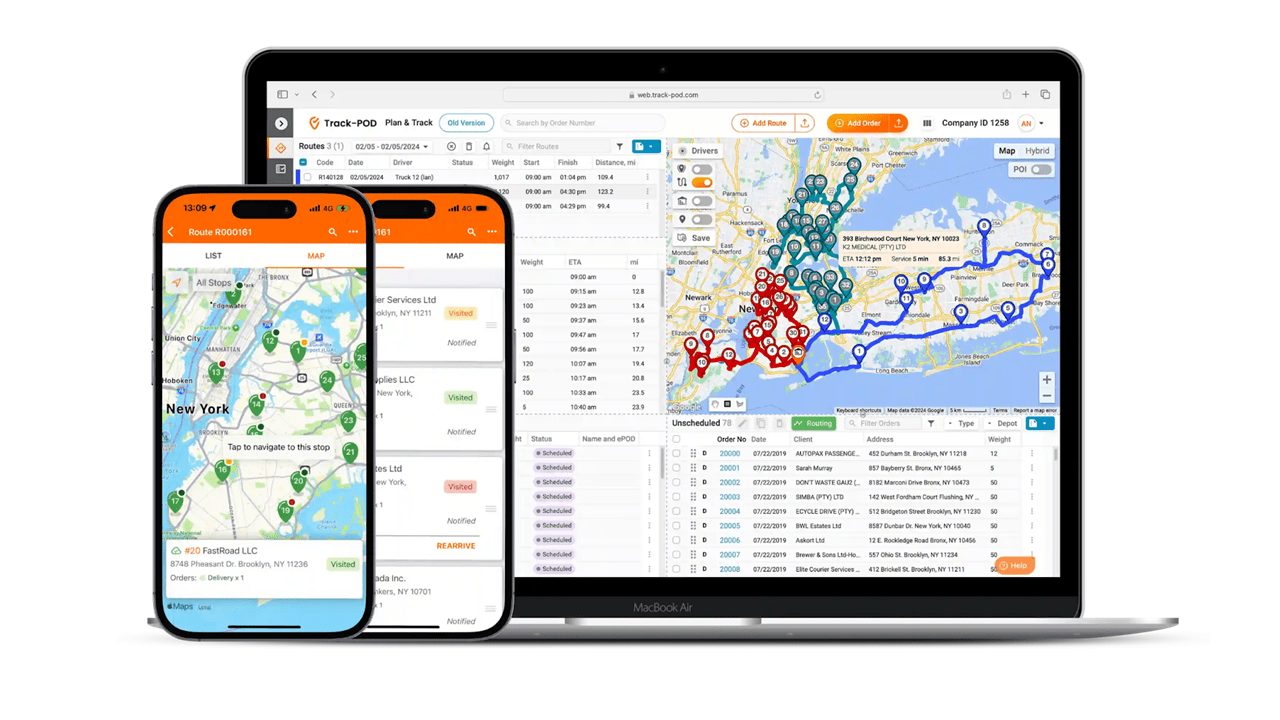

Zenotris worked with logistics and warehouse teams to implement targeted, low-risk improvements, including:

- Optimised WMS–TMS handoff triggers

- Automated alerts for stalled orders

- Standardised exception resolution paths

- Dispatch cut-offs adjusted based on real execution data

✔ No system replacements

✔ No additional headcount

✔ No disruption to live operations

Measured Results & Business Impact

Within 90 days, the logistics operator achieved:

- 27% reduction in missed delivery windows

- 18% reduction in manual exceptions

- Lower penalty, fuel, and re-delivery costs

- Improved warehouse–transport coordination

- Higher service reliability for retail clients

The improvements delivered direct EBITDA impact, not just operational visibility.

Operational Improvements Implemented (Within 90 Days)

Why Process Intelligence Works for UK Logistics

⚪Event data already exists in WMS, TMS, and ERP systems

⚪Bottlenecks are operational, not organisational

⚪Improvements can be executed quickly

⚪Results are measurable in time, cost, and throughput

This was not a dashboard project. It was a logistics process optimisation initiative with real financial outcomes.

What This Means for UK Logistics & Supply Chain Leaders

If your logistics operation struggles with:

⚪ Missed delivery windows

⚪ High last-mile failure costs

⚪ Manual exception handling

⚪ Ongoing operational firefighting Then the problem is rarely visibility —it’s process flow across systems.

Zenotris helps UK logistics organisations identify, quantify, and eliminate operational inefficiencies using process intelligence — fast.