Identifying systemic last-mile failures using event-level process mining

Case Study Snapshot

Industry: Logistics & Last-Mile Distribution

Geography: United Kingdom

Delivery Model: Slot-based urban and regional deliveries

Primary Issue: Repeated delivery slot failures driving penalties and rework

Zenotris Capability Used: Event-level process mining

Annual Financial Impact: £1.2M recovered

Outcome Type: Cost recovery + delivery predictability

Today’s logistics economy rewards innovators. Technology is no longer considered a luxury; it is the foundation of competitiveness. Those who use tools like process intelligence increase their resilience, visibility, and agility. These characteristics are crucial in marketplaces experiencing change, uncertainty, and increased customer demands.

Firms that fail to innovate risk falling behind. Manual oversight cannot keep up with the complexities of global logistics. While competitors streamline and optimize, laggards lose money, customers, and reputation. In a business where every second counts, inefficiency may soon become the costliest liability.

Technology enables logistics organizations to not only survive, but grow. Businesses achieve long-term growth by combining data and action. others that act early have a competitive advantage over others who wait until inefficiencies destroy value.

The Commercial Problem: When Delivery Slots Become a Liability

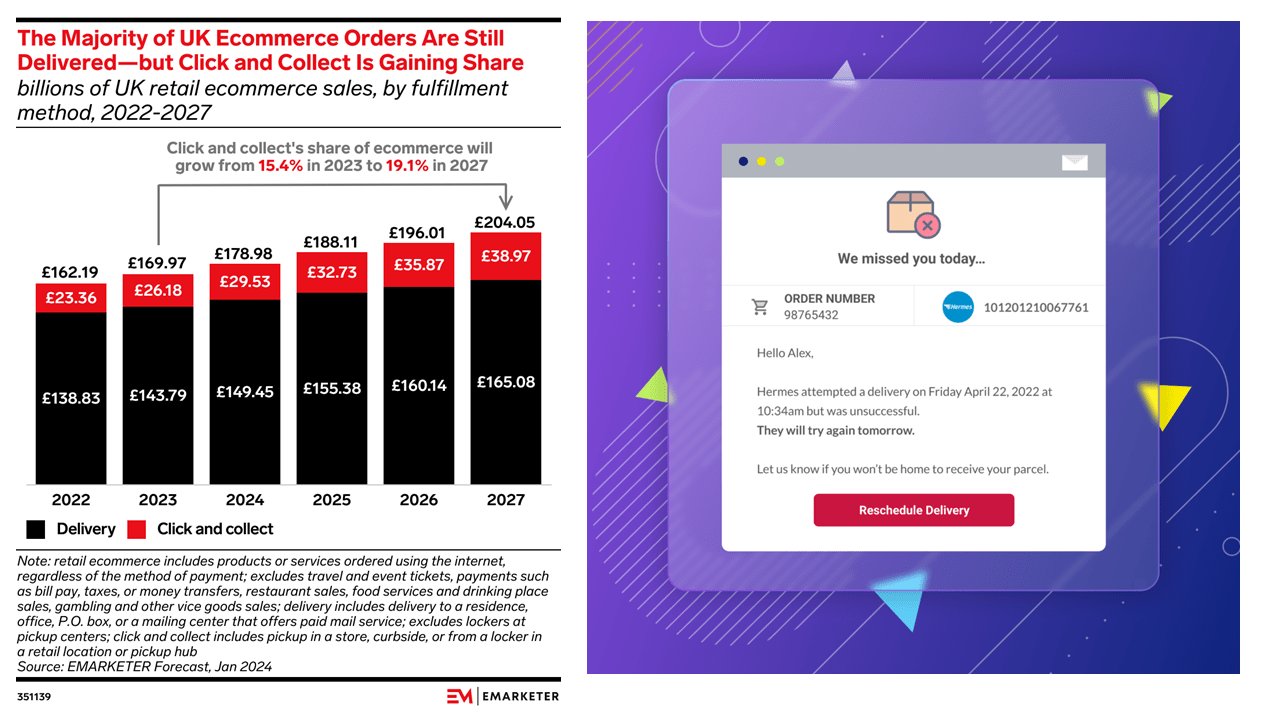

The client operated a slot-based last-mile delivery model, committing to fixed delivery windows for retail and e-commerce customers.

Over time, delivery slots — once a competitive advantage — became a financial risk:

- Penalty charges for missed or failed slots

- Repeated re-delivery attempts

- Rising fuel and driver overtime costs

- Reduced trust from enterprise customers

- Difficulty forecasting weekly delivery performance

Despite acceptable on-time delivery averages, penalties continued to rise.

Leadership knew something was wrong — but not where value was leaking.

Why Slot Failures Were Hard to Fix

Traditional last-mile analysis focused on:

- Route optimisation tools

- Driver performance metrics

- GPS-based delay reporting

These approaches treated failures as isolated incidents, often attributed to traffic, customer availability, or driver behaviour.

What was missing was visibility into how delivery slots actually behaved across execution steps — from slot creation to final confirmation.

Zenotris Method: Slot-Level Process Intelligence

Zenotris approached the problem differently.

Instead of analysing routes or drivers, we analysed delivery slots as processes.

Using event-level process mining, Zenotris reconstructed the full lifecycle of each slot using data from:

⚪ Slot creation and allocation events

⚪ Dispatch and reassignment logs

⚪ Driver app interactions

⚪ Delivery attempt and failure timestamps

⚪ Penalty and re-delivery records

Each delivery slot was treated as a unit of economic value, not just a time window.

What the Data Revealed

The analysis uncovered patterns that were invisible in standard reports:

⚪ Certain slots consistently failed regardless of route or driver

⚪ Late slot reassignment dramatically increased failure probability

⚪ Re-attempt logic was reinforcing failure instead of correcting it

⚪ Planning assumptions did not reflect real-world execution times

Key Insight

⚪ A small subset of delivery slots was structurally unviable — yet repeatedly reused.

Result: 15–20% of slots were responsible for the majority of penalties and re-delivery costs.

Rather than expanding fleet capacity or changing routing software, Zenotris helped the client implement slot-focused operational changes:

- Identified and retired high-risk delivery slots

- Redefined slot buffers based on real execution data

- Adjusted reassignment rules to prevent late-stage failures

- Introduced slot-risk scoring before dispatch

- Reduced repeated attempts on historically failing slots

All changes were process-level, not system replacements.

Financial & Operational Impact

Within three months, the organisation achieved:

- £1.2M in annualised penalty and re-delivery cost recovery

- Predictable delivery performance across peak periods

- Reduced fuel waste and driver overtime

- Improved customer confidence in committed delivery windows

Most importantly, leadership regained control over slot economics.

Why This Case Is Different

This was not about:

- Faster picking

- Better routing

- More drivers

It was about understanding which delivery promises should never have been made in the first place.

By shifting focus from delivery execution to slot viability, the client moved from penalty management to delivery predictability.

Corrective Actions Taken

Why Event-Level Process Mining Works for Last-Mile Logistics

⚪ Slot failures are process-driven, not random

⚪ Root causes repeat across time and geography

⚪ Event data already exists across delivery systems

⚪ Fixes are fast, measurable, and scalable

This engagement transformed last-mile delivery from a cost centre into a controlled operation.

What This Means for UK Logistics Leaders

If your organisation is struggling with:

⚪ Rising delivery penalties

⚪ Repeated failed slots

⚪ Unpredictable last-mile costs

⚪ Customer pressure on delivery guarantees

The issue is likely slot design and execution logic, not effort or intent.

Zenotris helps logistics organisations identify which processes destroy value — and how to fix them using process intelligence.